Production and processing of plastic materials

Misolet is able to process plastic materials such as ABS, Polycarbonate, POM (derlin), PVC, PEEK and PTFE as well as Nylon6 and Nylon66+fv30%.

Materials that can be used for multiple industrial sectors.

Misolet is able to process plastic materials such as ABS, Polycarbonate, POM (derlin), PVC, PEEK and PTFE as well as Nylon6 and Nylon66+fv30%.

Materials that can be used for multiple industrial sectors.

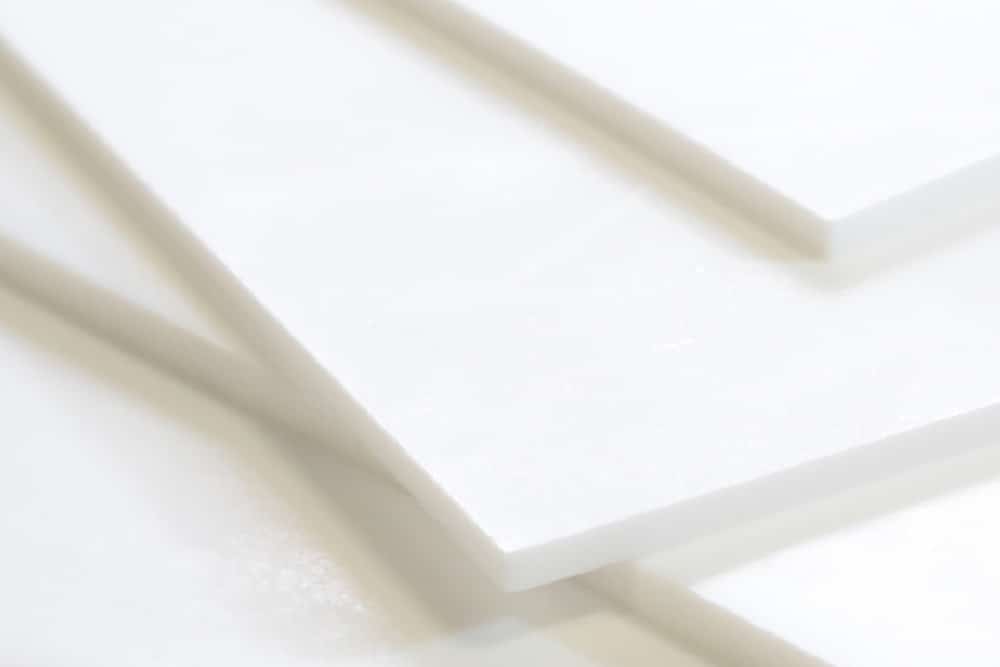

Il polycarbonate it is a material particularly appreciated for the transparency, longevity and its electrical and thermal insulation properties. It is also lightweight, supports heavy loads and resists abrasion, steam and weather. Good workability, excellent impact resistance and good sound-absorbing quality, it can be bent both hot and cold and is suitable for thermo-forming. It can be glued.

It has a temperature range from –100 C° to +120 C° and is classified UL-94 V0, but poor chemical resistance. Available in 2050×1250 and 3050×2050 slab format.

Il polycarbonate it is a thermoplastic polymer that is used in many industrial sectors, often in place of glass. It finds space in various applications such as: protections for machinery, industrial carters, electrical panels, displays, signs, covers, dividers, luminous displays, signs, interior signs, PPE protective visors, vending.

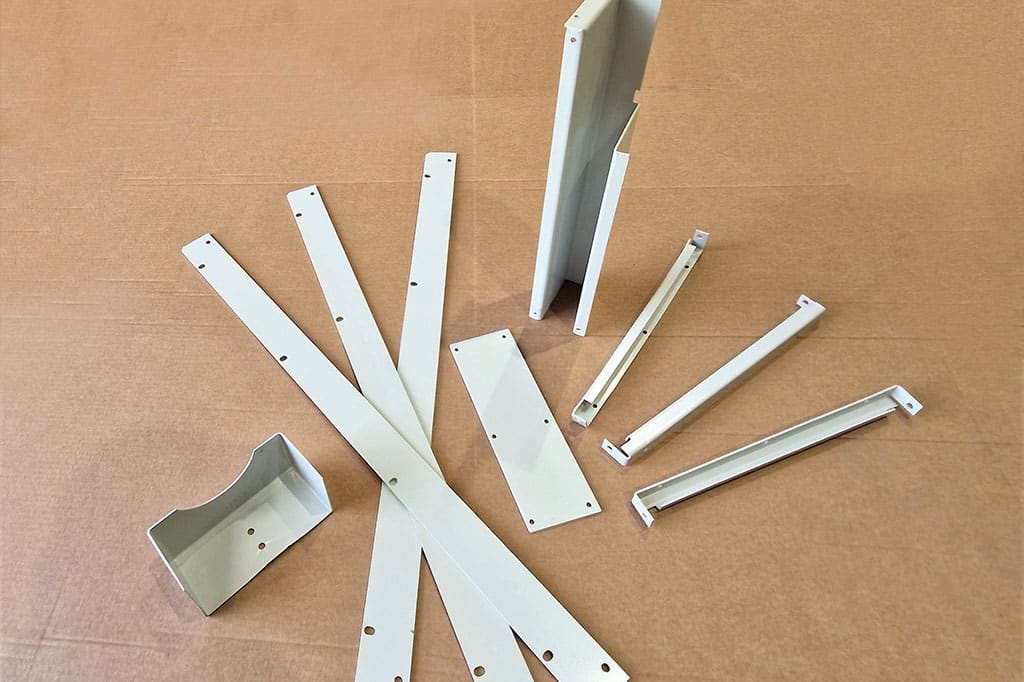

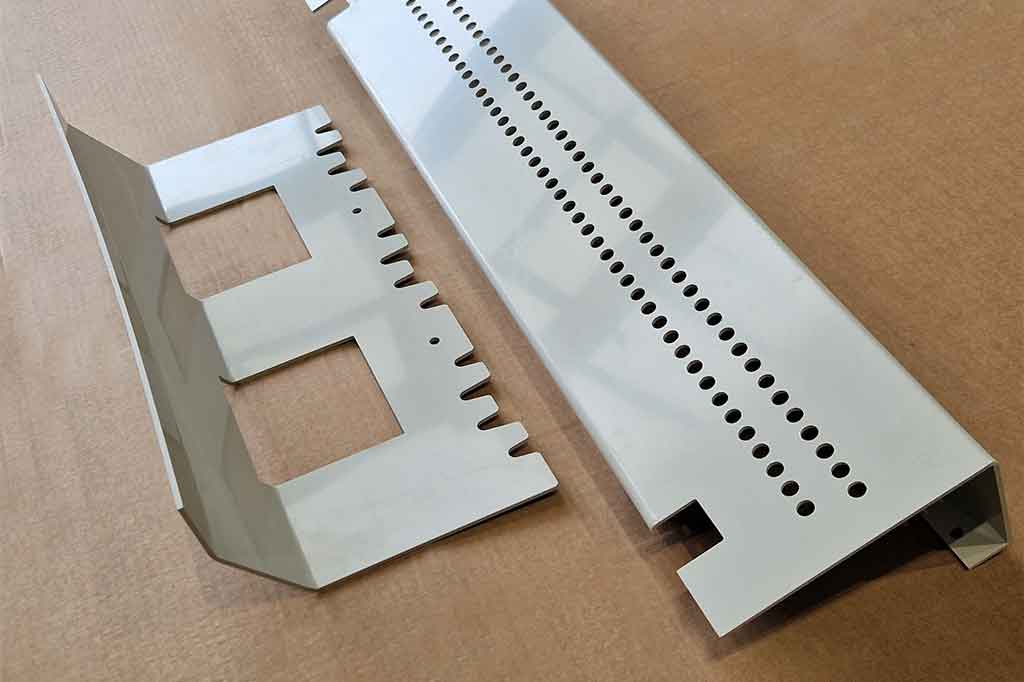

Acrylonitrile-Butadiene-Styrene, or as it is more commonly called ABS, is a thermoplastic polymer used in various industrial sectors.

Its greatest use is found in the creation of printed, light and rigid objects. Some examples are: pipes, assembly boxes for electronic and electrical components, toys, control panels of household appliances, car dashboards, musical instruments such as flutes, etc. Misolet specializes in the mechanical processing and bending of this

material for industrial applications and particular components. This material, of the self-extinguishing UL94-V0 type, is available in 2000×1250 format sheets. ABS is also commercially supplied in HB class.

ABS is characterized by its impact resistance and good rigidity.

It is a very light material and for this reason it is also often used in the automotive sector. ABS has excellent electrical resistance and can be used thermally from -20°C to +80°C. On the other hand, we find poor resistance to atmospheric agents. For this reason, indoor use is recommended only.

ABS is suitable for mechanical processing and hot bending, also lending itself to thermoforming.

With this material we create products using gluing techniques with specific glues.

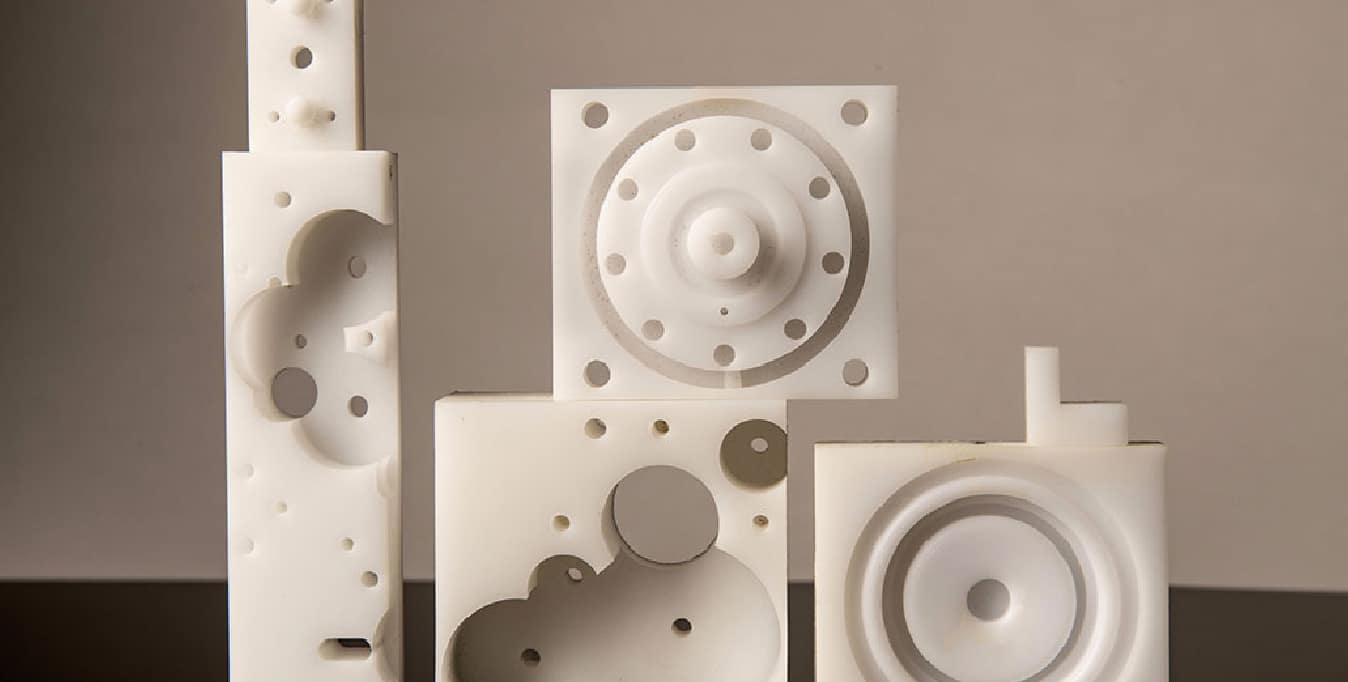

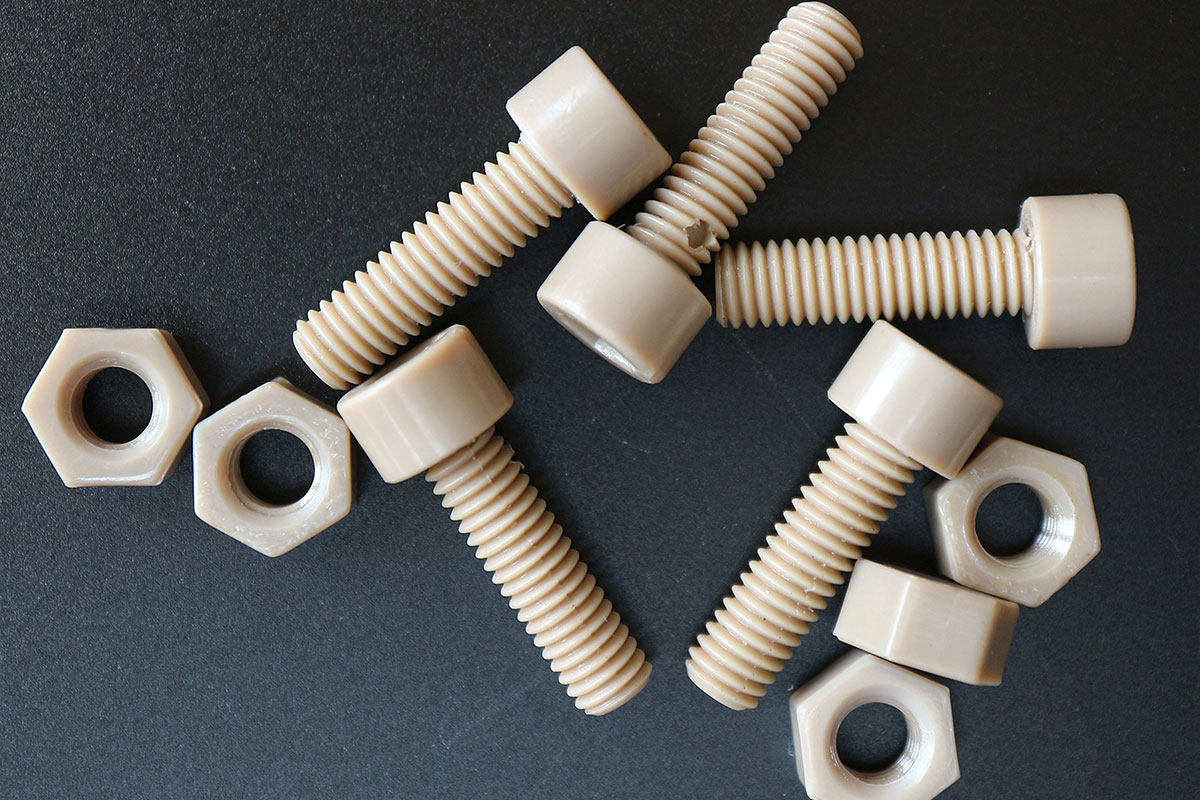

Nylon polymers, or (PA), are a family of polymeric materials. The qualities that distinguish these materials are: elasticity and robustness. These characteristics are contained in a thread as thin as that of a spider's web.

Nylon 6 – also called PA6 – is a polyamide material obtained from caprolactam. In the textile sector, synthetic fiber is used to make tights, socks in general and some sports clothing. In the industrial sector, however, it is used for processes which require good mechanical resistance to wear and impact. Another name for Nylon 6 is polyprolactam. This material is also used to make plastic gears.

Nylon 66, known as PA66, is a type of plastic, derived from petroleum, with heavy use in the textile industry and with applications in the industrial sector serving La Misolet. The material has excellent hardness and rigidity qualities, good tensile strength and stability to temperature variations. It has lower water absorption than Nylon 6 and has excellent resistance to oils, greases and solvents. Furthermore, it is self-extinguishing with a UL-94 V2 rating. Fabrics made of continuous thread, without twisting, have little resistance to snagging (pulled threads).

PA66 + GF30 is a polymer filled with 30% glass fibre, which leads to the sheet having high mechanical resistance. Nylon 66 + GF 30, therefore, increases its resistance to compression, abrasion and bending.

It is used in many industries, including mechanical, electrical, chemical and food.

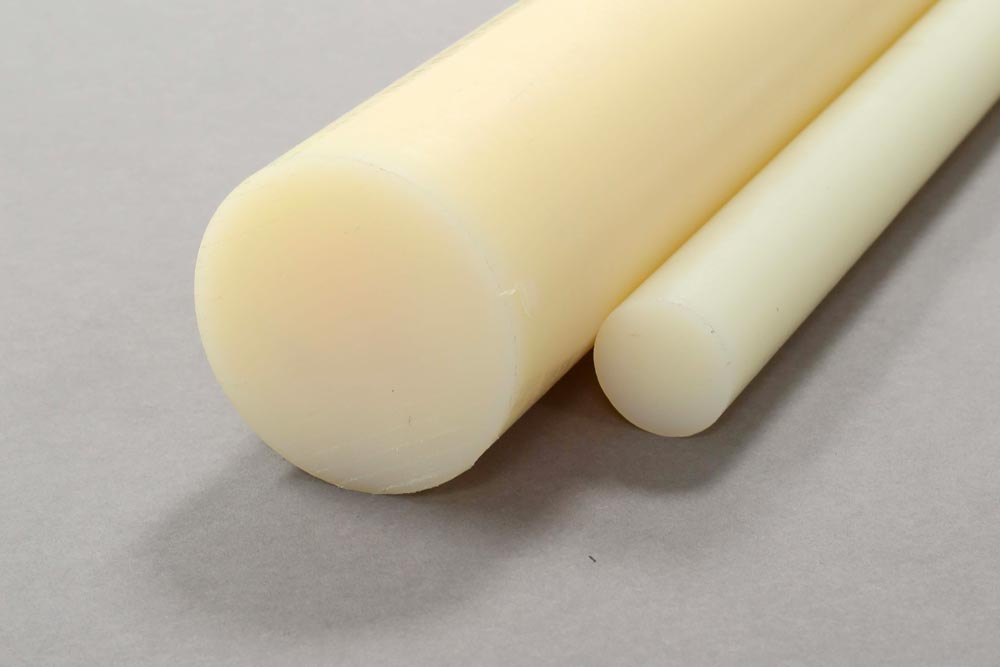

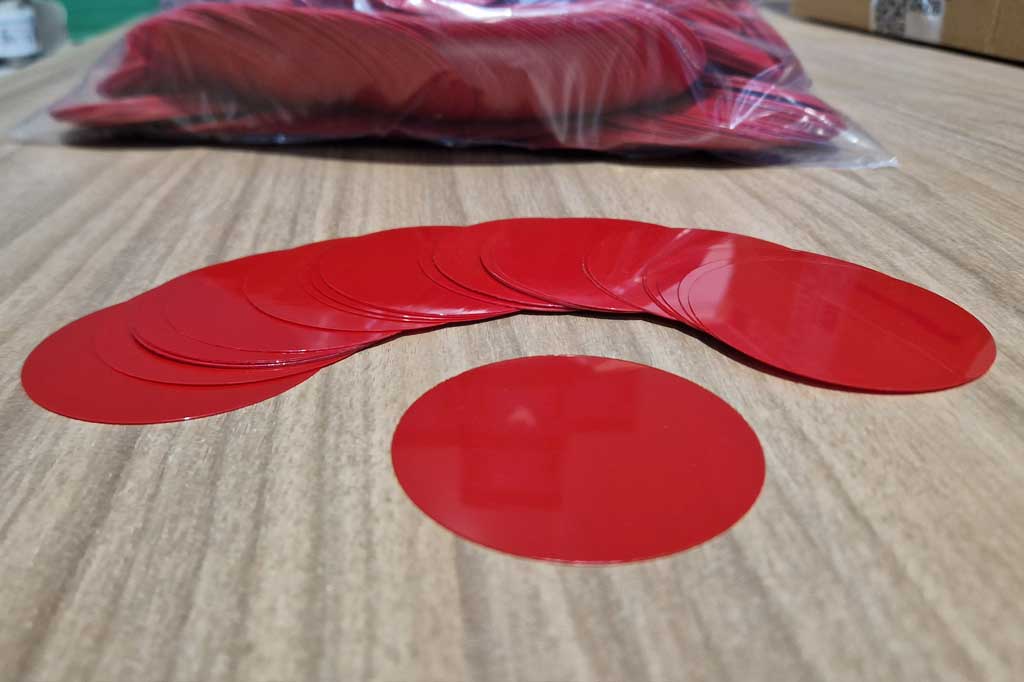

POM, commercial name of Polyoxymethylene, or acetal resin, is obtained through reactive extrusion through the polymerization of the formaldehyde monomer. It is also called "Delrin" and is a crystalline polymer from which various mechanical parts can be produced. Among these, the round POM tube is suitable for the production of components for chemical plants.

POM has high mechanical resistance and being hygroscopic it is also used as an electrical insulator.

Furthermore, POM has the peculiarity of having excellent dimensional stability and chemical resistance.

The material – available in sheet, tube or round – is used in contact with foodstuffs as it is physiologically inert.

POM is used for the creation of mechanical parts most suitable for the pharmaceutical and food industries. Other application sectors of the POM material are: mechanical industry, car components and electronics industry. With this material are produced: gears with low modules, bearings, pumps, flanges, sliding wheels, guides, etc.

PVC is the commercial name of Polyvinyl chloride, also known as polyvinyl chloride polymer.

PVC is made from natural raw materials and is one of the most used plastic materials in the world. Misolet sells and processes sheet, tube and round formats.

PVC has among its characteristics a high resistance to fire, as it expands and carbonizes when burned. Furthermore, it is a self-extinguishing material, classified UL94-V0, which stops burning when the flame source is removed.

PVC has excellent properties as an electrical insulator. But it is its versatility of use that makes it so requested and used.

PVC is made available on the market through hot molding.

This material is used extensively in the construction industry and the textile industry.

Some applications are the production of construction pipes, pump parts, rings, flanges and much more.

PTFE is a fluorine polymer highly appreciated for its characteristics as it has a low friction coefficient - both static friction and dynamic friction. Furthermore, it has excellent chemical resistance and a high degree of resistance to low and high temperatures (from –200° C to +260° C).

PTFE is an electrical insulator that stands out for its non-stick properties.

It has poor mechanical properties, such as traction and compression, even under very limited weights.

The poor mechanical properties make this material useful for making non-stick gaskets and pans. Teflon is also used in the electrical industry and in the automotive sector to help make engines. Other uses are in the creation of rings, stuffing boxes, valve balls, pipe expansion joints, protective coatings, insulators, bushings, piston rings and piston seals.

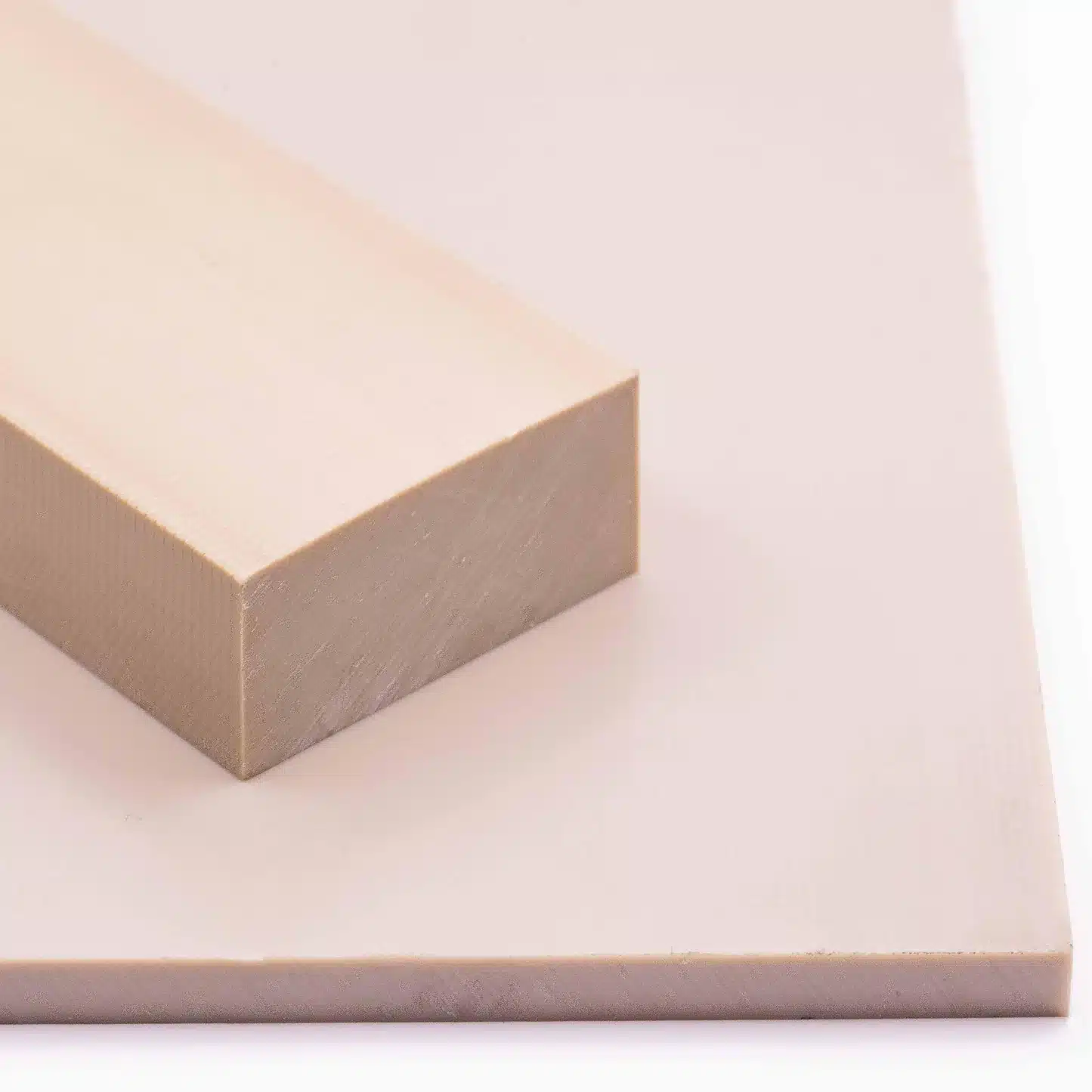

PEEK is polyether ether ketone, a thermoplastic polymer with excellent performance in terms of durability, scratch resistance and high temperatures.

The type we supply is without fibreglass, it can therefore be used in the food sector as well as being classified as self-extinguishing UL94-V0. This material is available for retail sale in sheet format.

PEEK stands out for its high mechanical resistance and has a tensile strength that varies from 90 to 100 MPa.

The material is self-extinguishing and has excellent dimensional stability, good resistance to chemical agents, and good electrical insulation. It also has excellent creep and wear resistance.

This polymer has a combination of thermal, chemical, scratch and wear resistance that finds application in various industries.

PEEK is processed through extrusion, injection molding and milling processes.

It finds application in numerous sectors due to its anti-corrosion, anti-stick and sliding characteristics. Some examples are the food, mechanical, electrical, chemical, nuclear, textile, furniture, construction, automotive and many other sectors.