Polyester glass is made of single-wire glass MAT non-woven fabric, impregnated with polyester resin. It has different technical names according to the international standard, although it is usually known as GPO3.

In the production of this material, continuous filament is used, which improves its mechanical characteristics of tensile strength. This allows cold blanking for thicknesses up to 5 mm.

It is also made with the SMC (Sheet Molding Compound) method, using chopped glass fiber as a base. This technique makes it more compact and suitable for removal processes, such as milling and turning.

This laminate is a V0 self-extinguishing layered insulation, with good mechanical and dielectric properties. It is used to produce both milled components and blanked parts.

GP03 Polyester Glass

| 2000 × 1250 | |

Property

Polyester glass is an insulating and self-extinguishing material, according to the UL94 V0 classification.

It has good dielectric properties and excellent arc resistance.

This material has two other important characteristics: excellent resistance to electrical tracking and traction. It means that polyester glass is a resistant insulator and tends to wear little, despite traction and stress.

It is also characterized by low water absorption and is certified according to the EN 45545-2 standard, therefore free of halogen substances with low smoke emission and a low toxicity index.

Applications

Sheet polyester glass is intended for use in electrical panels, energy transformers and high voltage, medium voltage and low voltage disconnectors.

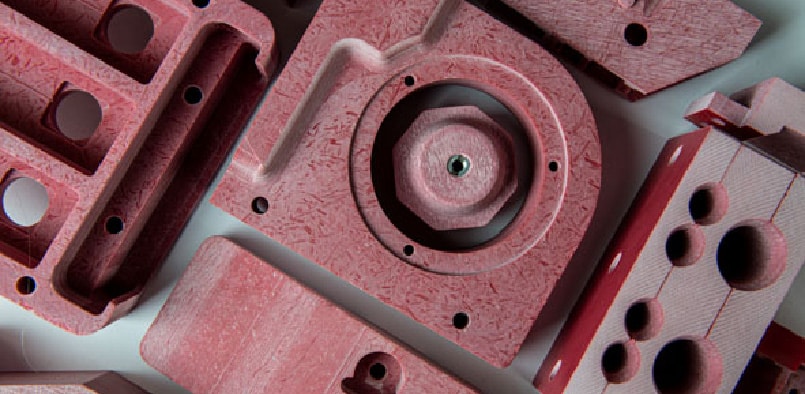

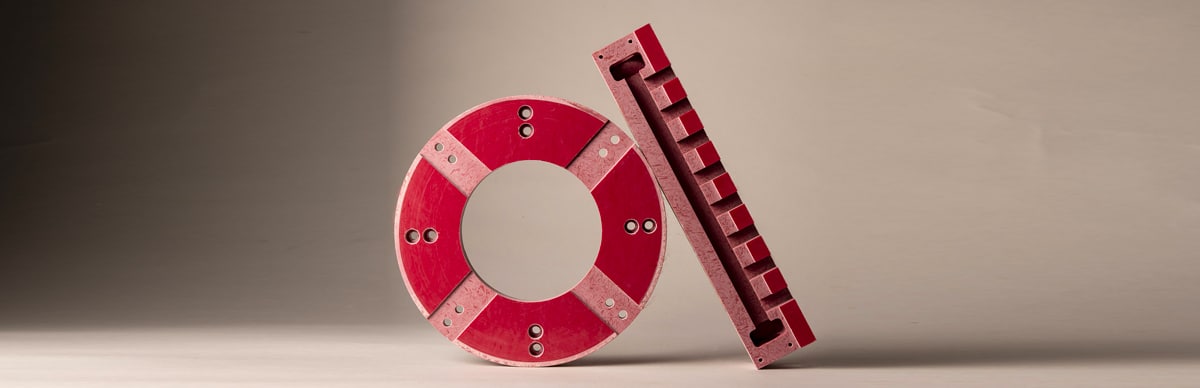

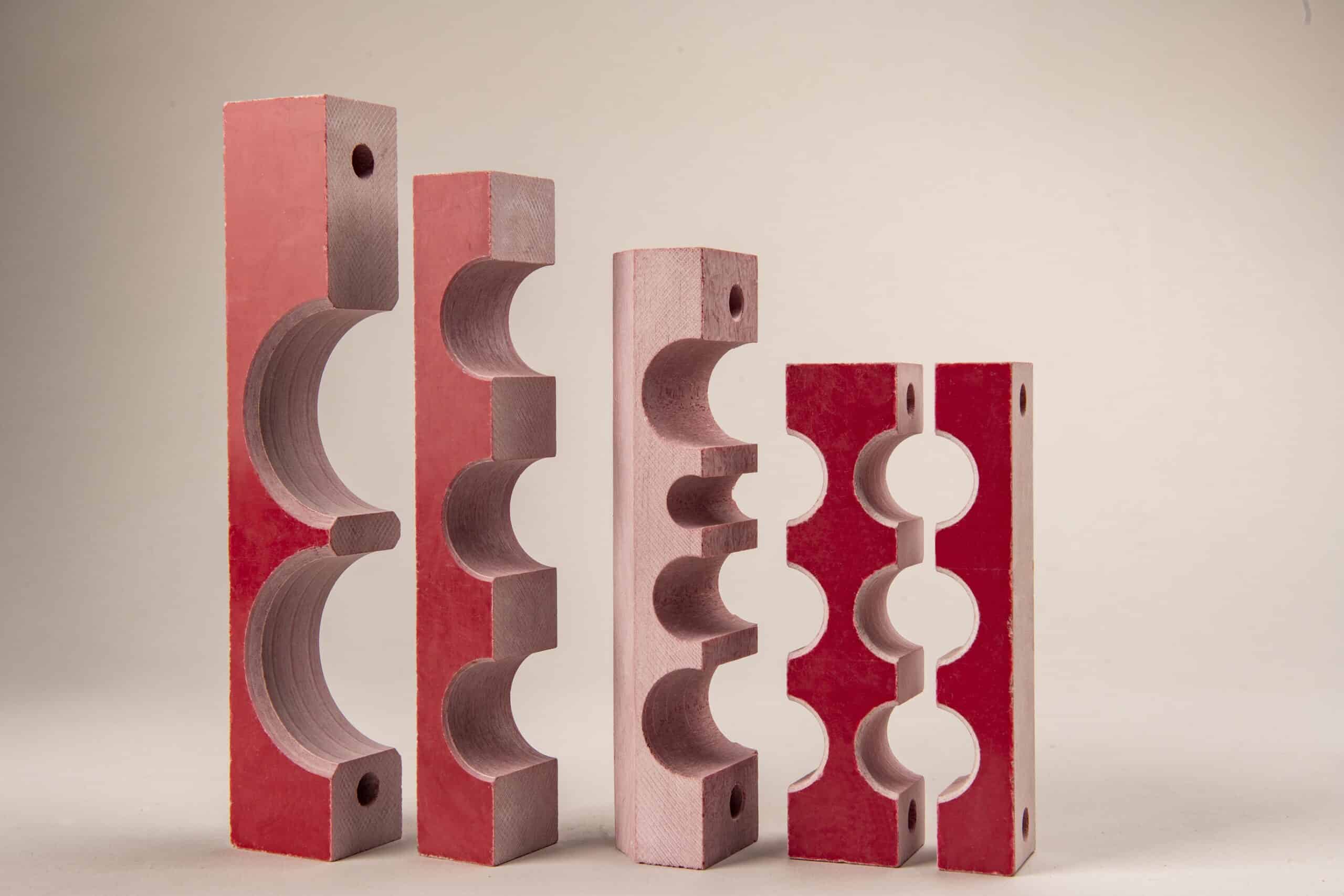

Vanes, air gaps, washers, support bars, protection panels, rings and gaskets are also produced with this material.

It is mainly used in the electromechanical, energy transport and railway sectors.

LGPO

Material of glass and polyester resin

| Standard | NEMA LI – 1 | GPO3 |

| CEI 15/10 | PV | |

| CEI EN 60893 | UP GM 203 | |

| DIN 7735 | Hmm 2471 | |

| Temperature class F (155° C) self-extinguishing | ||

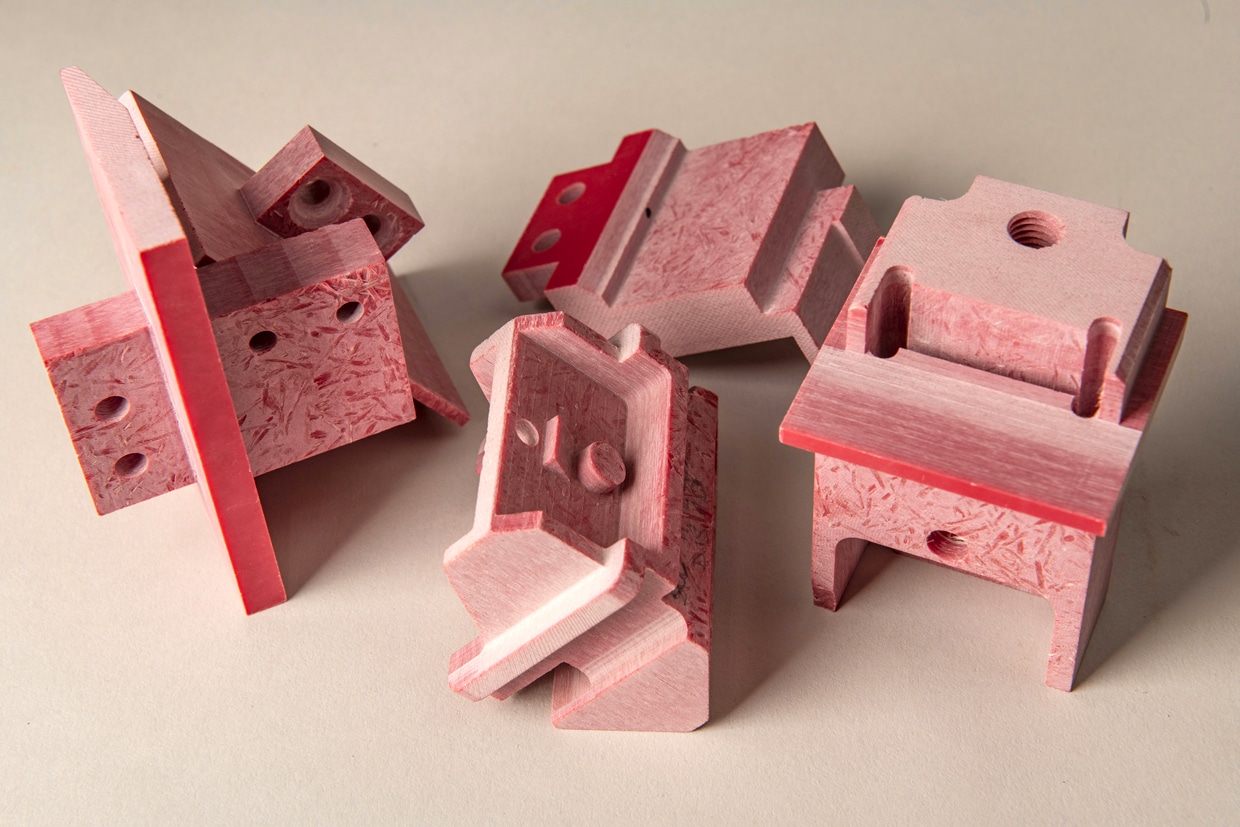

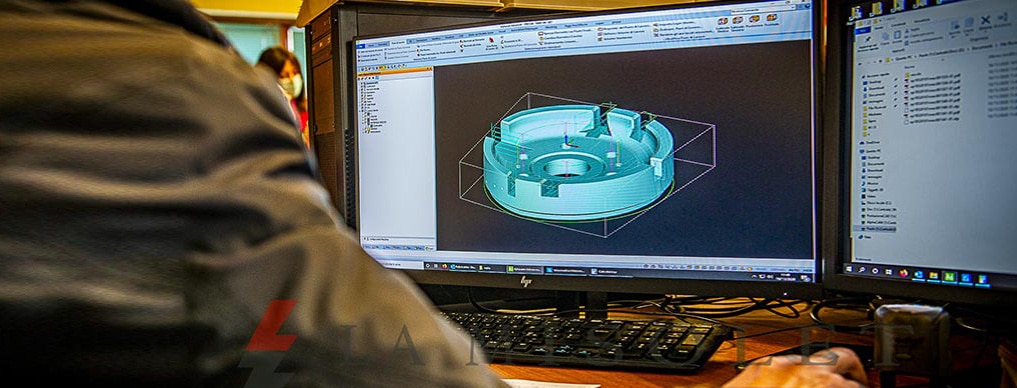

Customized mechanical manufacturing

Misolet specializes in mechanical processing of details according to the customer's design, both for consolidated applications and for new projects.

Milling and turning These are the main mechanical processes we use to create customized items, starting from the raw material.

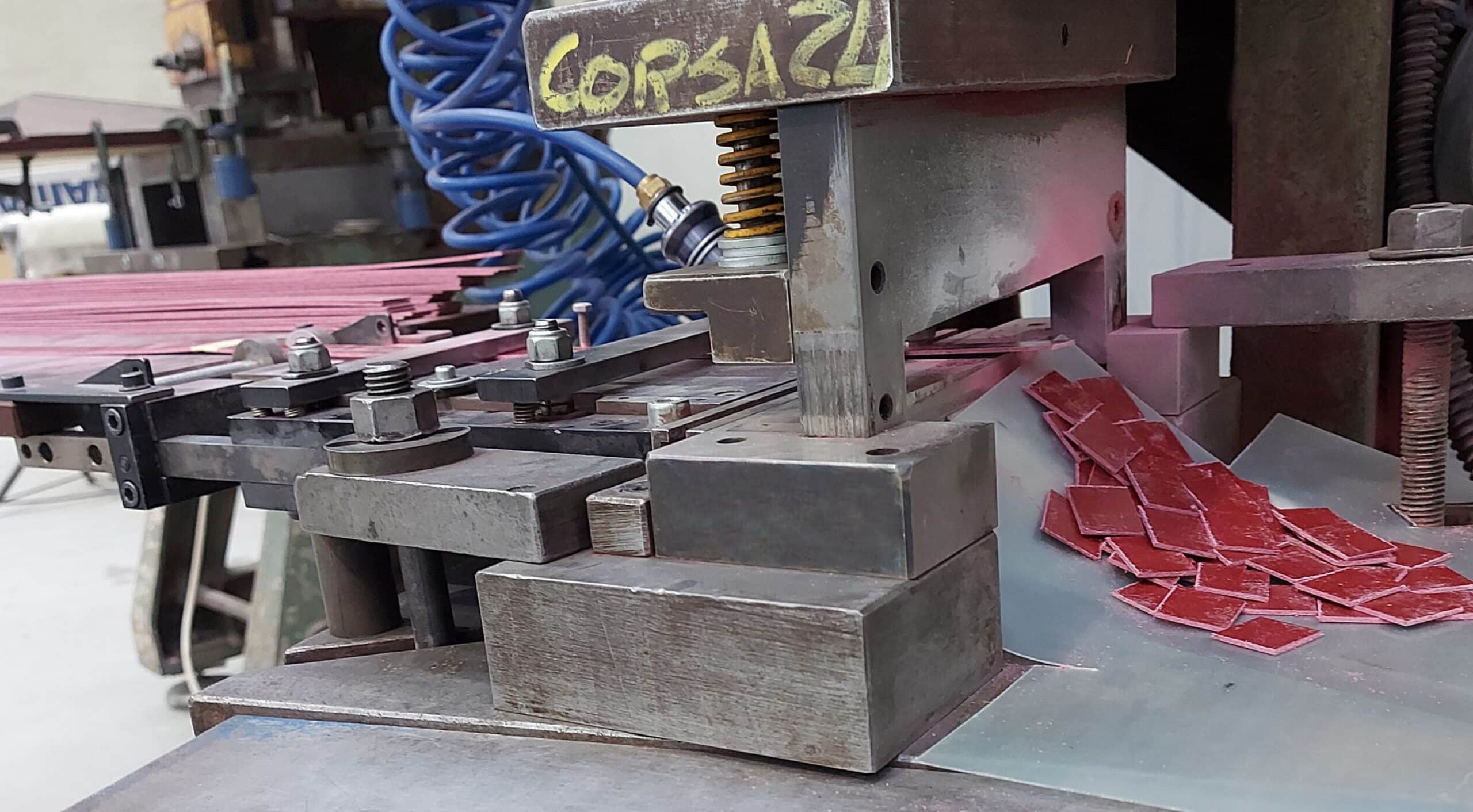

Shearing

Blanking is a cold mechanical process, which we carry out on all the materials offered up to a maximum thickness of 5 mm.

We also offer die cutting and punching services.

Cutting

We offer an efficient service cut to size on the sheets of all our materials.

The cuts happen in lists, panels, stripes and bars of the desired size.

By using the program for nesting, we optimize the use of slabs by avoiding waste of material.

Assembly and direct sales

Misolet offers slabs for direct sale and immediate delivery.

Customers can also take advantage of complementary assembly and bonding services for different types of materials.

We assemble particular products, both with other insulating components,

both with metal components also for processing, such as inserts, screws and pins.