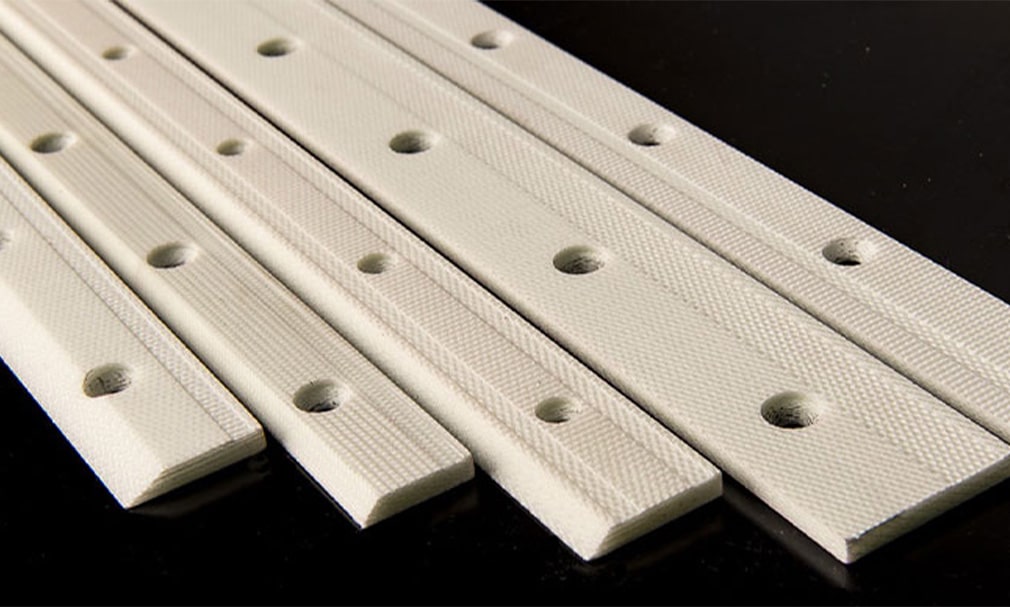

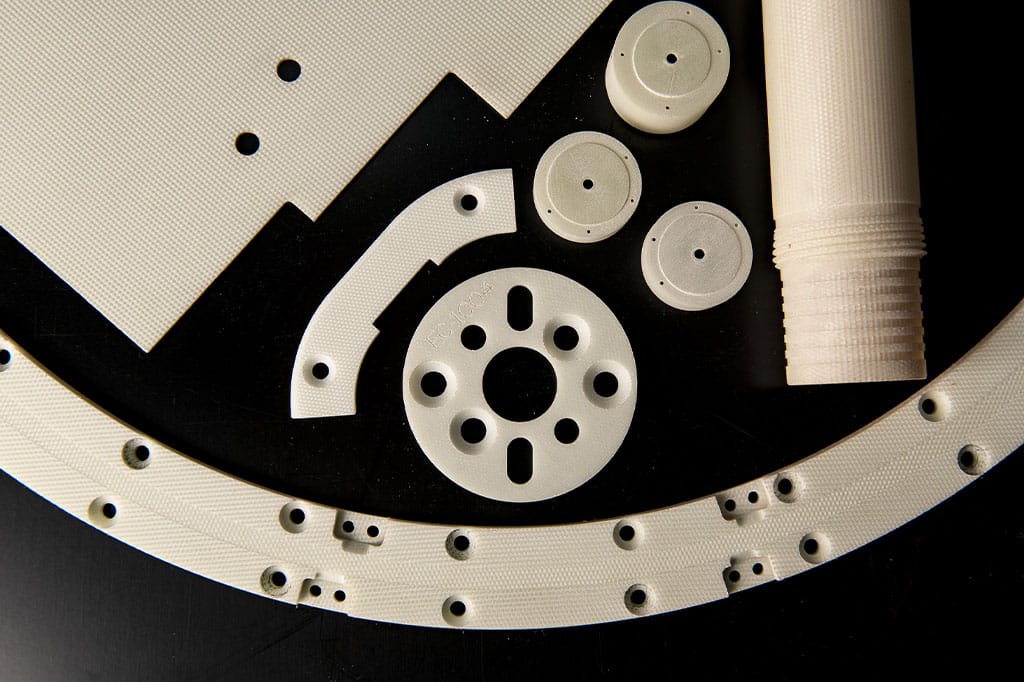

Production of melamine and silicone Vetronites

Melamine and silicone fibreglasses are composite materials, derived from glass, which are Made using resin melamine or silicone and fiberglass fabric.

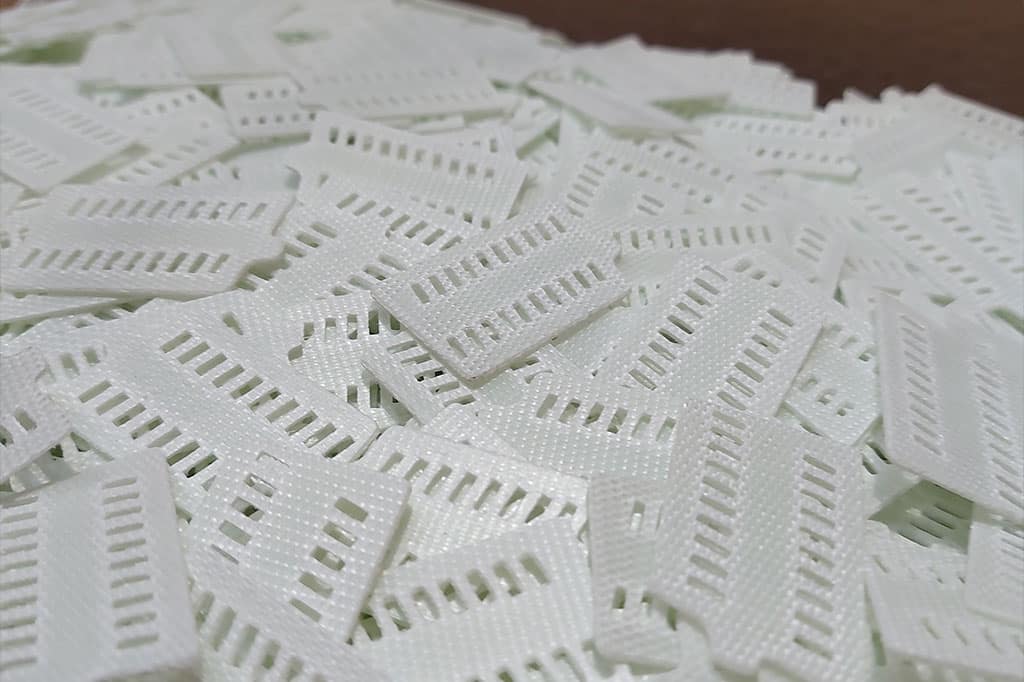

These types of vitronite are laminates made by means of a thermal process under pressure and stand out as good thermal and electrical insulators, suitable for use as an insulating part in the grooves of high-temperature motors, anti-arcing devices for switches and similar applications.

Both are self-extinguishing, mechanically inferior to epoxy glass, but have high resistance to creeping currents (tracking) and electric arc. This means that they tolerate the sparks that are released when a switch turns on or off the power well.

For this reason we recommend application as disconnectors for low and medium voltage.