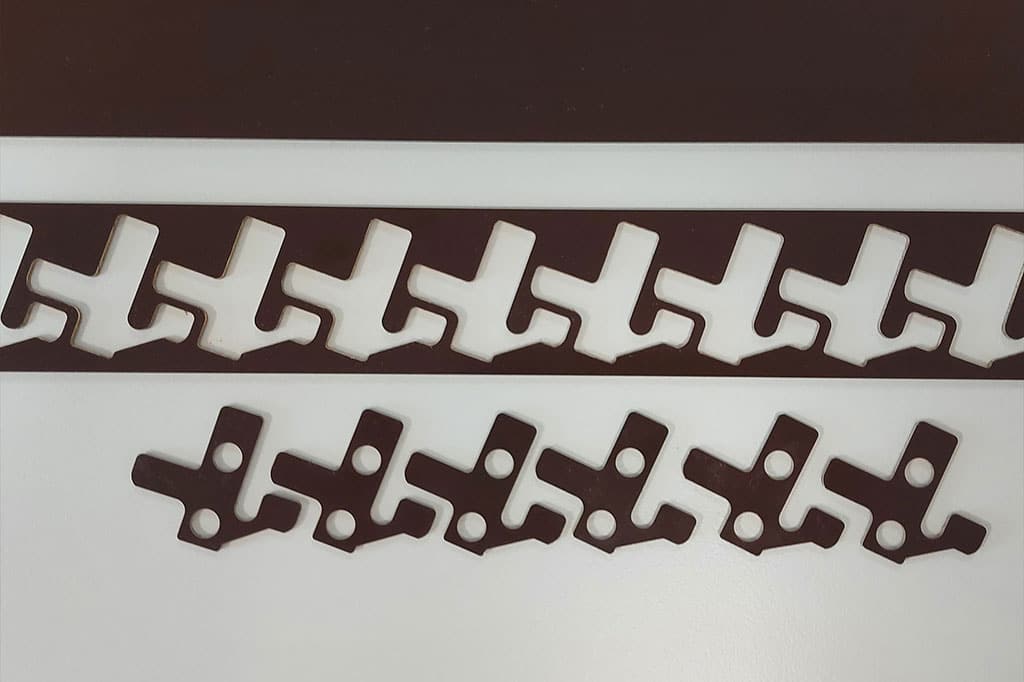

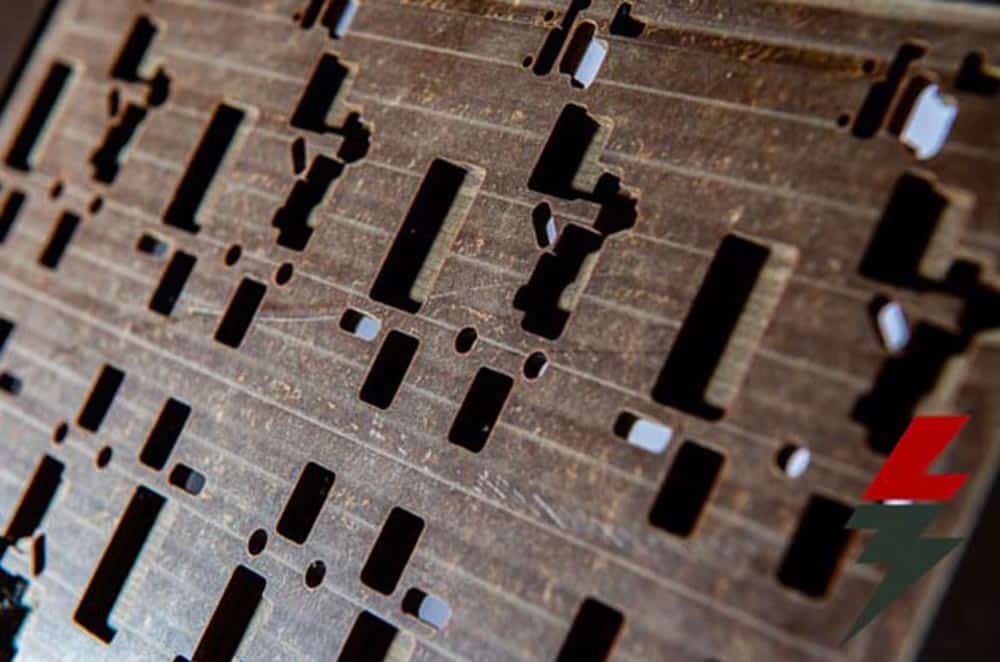

Productions with bakelized paper

Bakelized paper is a composite laminate made of phenolic resin and cellulose.

It is a composite material of Bakelite, a thermosetting polymer, combined with sheets of Kraft paper, the result of a stratification process. Bakelized paper is often still identified by its trade name Dellitis.

Like bakelized canvas, paper also falls into thermal class E, with an effective insulation temperature of 120° C.

In the event of open flames, it burns slowly and is classified as self-extinguishing class HB by the UL-94 standard, which defines the tests and flammability classes for materials used in industrial components for applications in electrical devices.